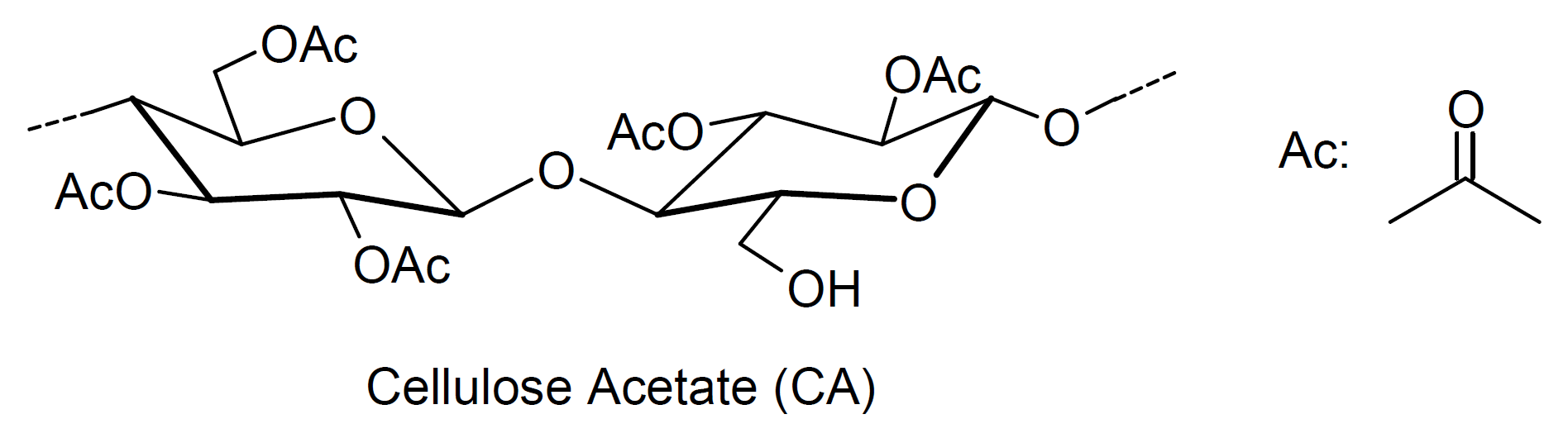

Cellulose Acetate (CA)

Properties and Applications

Cellulose acetate (CAc, CA) and its co-esters are the most

important esters of cellulose.1 CAc is a crystal clear,

tough, and flexible plastic and one of the most stable cellulose

derivatives. It has excellent chemical resistance to organic and

inorganic weak acids, hydrocarbons, vegetable oils, and the like.

Unlike cellophane, it is thermoplastic and

easier to process.

Films made of this plastic have exceptionally low haze, high moisture vapor transmission but low water permeability.

Pure CAc is obtained by acetylation of the cellulose hydroxyl

groups with acetic anhydride in acetic acid and in the presence of

a strong acid catalyst. CAs can be broadly classified into two types:

cellulose diacetate (CDA) and cellulose triacetate

(CTA). The former has a degree of acetylation of about 2.4 and the latter of

about 2.9, respectively. The two types of CAc have somewhat different physical properties;

in general, the gas and moisture permeability decreases with increasing acetyl content, whereas the chemical resistance increases.

Often plasticizers are added or

mixed ester of cellulose like cellulose acetate-butyrate (CAB) and

cellulose acetate-propionate

(CAP) are produced which have improved flexibility, toughness, and moisture resistance.

Cellulose acetate is widely used for industrial and consumer goods

applications. Important uses include textiles (fibers and threads for quality fabrics); plastic films such as optical film for LCD technology and antifog goggles; and consumer products such as cellulose based filters,

window cartons, and labels. One of the most important uses of

CAc, CAB

and CAP resins is in coatings including metal and wood coatings, gravure and flexographic printing inks, graphic arts, ink jet printing inks,

automotive clear coats, and general industrial coatings. Cellulose

ester resins, in particular the mixed esters are beneficial in reducing surface defects such as cratering, fish eyes, and organge peel in various

resin systems including melamine-acrylic clearcoats.

Manufacturers & Distributors

Companies |

Brands

|

1According to MarketeandMarkets™, the cellulose acetate market is expected to grow from USD 3.6 Billion in 2016 to USD 4.9 Billion by 2022.

Source: marketsandmarkets.com, April 2018.